NOR-FROST: A near-surface fibre optic sensing test site

NOR-FROST is the new NORwegian FibeR Optic Sensing Test site in the backyard at NORSAR!

At NORSAR construction just finished of a new and unique test facility: NOR-FROST, the Norwegian Fibre Optic Sensing Test Site. NOR-FROST is open for collaboration and welcomes experiments from third parties.

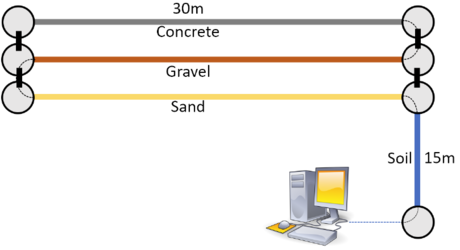

NOR-FROST is located on the premises of NORSAR, at Kjeller, Norway, just outside Oslo. Fibre optic cables have been deployed along three parallel trenches of 30 m length and 1m depth filled with concrete, gravel, and sand respectively. The trenches are 150 cm apart. Additionally, for operational purposes, a 15 m trench is oriented perpendicular to the three main trenches and is filled with normal soil. Figure 1 shows a map-view sketch of the geometry. At the end of each trench is a plastic “manhole” (Figure 2) with 1 m diameter to provide access for work and repairs such as splicing. Gravel at the bottom is intended to improve ground water drainage. Each adjacent manhole is connected with a single 11 cm-diameter, standard plastic pipe.

Figure 1: Map view sketch of the NOR-FROST site. Manholes at the end of each trench allow for easy access for future expansion of the site.

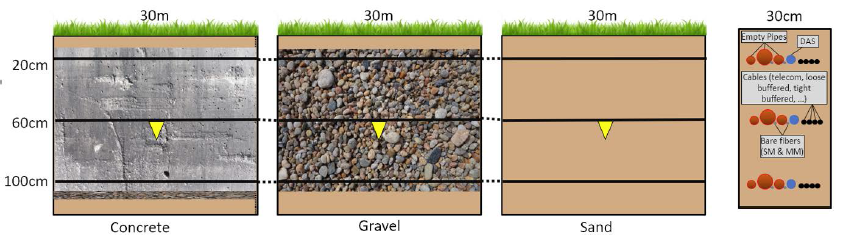

Various fibre cables from different vendors are laid out in 3 depths (at 20, 60 and 100cm) in each trench (Figure 3). Including some buffer length, this arrangement gives a total length of 350m for each cable. Empty pipes allow for retrofitting the site with more cables in the future. We also buried 3-component 4.5Hz OYO-Geospace geophones (GS11D) in the centre of each of the 3 trenches, just below the 60cm depth cables. The geophones’ Chanel 2 components are aligned parallel to the fibre cables.

Figure 3: Cross-sections of the 3 trenches filled with different material. Each layer consists of various cables and empty pipes for future expansion. Yellow triangles mark the positions of geophones.

This animation shows the path of a laser pulse along a fiber:

The cables installed permanently are:

- SOLIFOS BRUsens DSTAS V13: This cable is a special sensing cable for strain, temperature and acoustic sensing (DSTAS). The outer sheath is made from a rather stiff polyamid with a rippled outer surface for better acoustic coupling. Two single-mode (SM) fibres are each in separate (tight-buffered) metal tubes. One additional SM loose-buffered fibre is in a separate tube.

- NEXANS telecom TBU LSZH: This cable is designed for indoor and outdoor installation and has a central strength member (Fibre Reinforced Plastic), with a buffered structure around. The design is reinforced by a layer of glass yarns. Four tight buffered SM fibres are inside this cable.

- NEXANS Multi-Purpose Cable MPC-1: This cable is designed for installation in lakes, rivers, sea, tunnels, ducts or as direct burial cable on shore. The cable consists of 12 SM optical-fibres contained inside a stainless steel tube which is also filled with water blocking compound and hydrogen scavenging material. The stainless-steel tube is covered with a polyethylene inner sheath, armoured with galvanized steel wires and then covered with a polyethylene outer sheath.

- Hexatronic Nano GAHL 2/A2: This is a slim, tight-buffered cable designed for microduct installations with high durability due to its integrated strength member. It has a coated glass fibre reinforced plastic centre core for strength inside a layer of UV-cured polymer which contains the primary coated SM G.657.A1 (bend-insensitive) fibres, protected by the outer low- friction sheath.

- Legacy cable: A legacy cable from the 1980s was also installed. The cable has a steel reinforced loose-tube construction and 4 multi-mode (MM) fibres.

- Bare fibres: Each layer and each trench have additionally 5 SM (G.652.D) and 5 MM fibres. The MM is again of unknown specification. 5 fibres of each should provide redundancy in case of breaking during construction. Handling each 30m stretch separately proved to be the easiest way of installing these bare fibres.

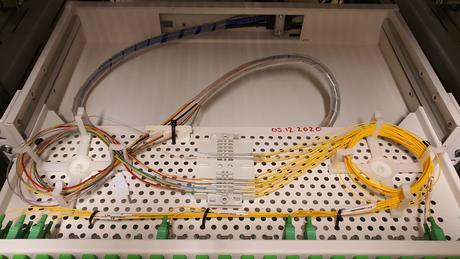

All cables end inside the NORSAR lab in the basement. A patch panel with SC/APC (SM) and SC/PC (MM) connectors to each fibre allows quick access to the individual cable loop. It also allows us to patch different combinations of fibres in series for simultaneous recording. Additionally, delay fibres can be included as desired to test performances at very long offsets.

With this site in place, we will be able to do fundamental research on DAS and DTS fibre sensing technology, such as investigating DAS transfer functions. We can compare and calibrate different fibres, cables, and interrogators. Different interrogators are on site as part of our distributed sensing instrument pool. Furthermore, repeat measurements throughout the seasons will allow us to investigate environmental effects on DAS response in the near-surface.

NOR-FROST has been made possbile with support from the project ECCSEL Research Infrastructure for Norwegian Full-Scale CCS (ECCSEL-NFS), financed by the INFRASTRUKTUR program of the Research Council of Norway.

Here is a time-lapse video of the construction:

Below you will find some impressions from the construction: